The automotive market is driven by demanding safety performance assessment programs, while at the same time facing increasingly restrictive CO2 emission reduction regulations. At the same, time reducing production costs is a requisite for automotive OEMs to remain competitive in the market. The cost-effective weight reduction of the vehicle’s structural components, known as Body in White (BIW), is one of OEMs’ main targets to master the most urgent market pressures. Such weight reduction is possible with lighter BIWs, made of Advanced High Strength Steels (>1.500 MPa), using a component production process known as Hot Stamping.

RUSHAI is a key enabling technology to achieve this challenging objective of cost-effective, lighter BIWs by way of a breakthrough ultra-fast hot stamping production system to produce light-weight components, quality-controlled by self-correcting, online AI, with an expected cycle time reduction of more than 70%.

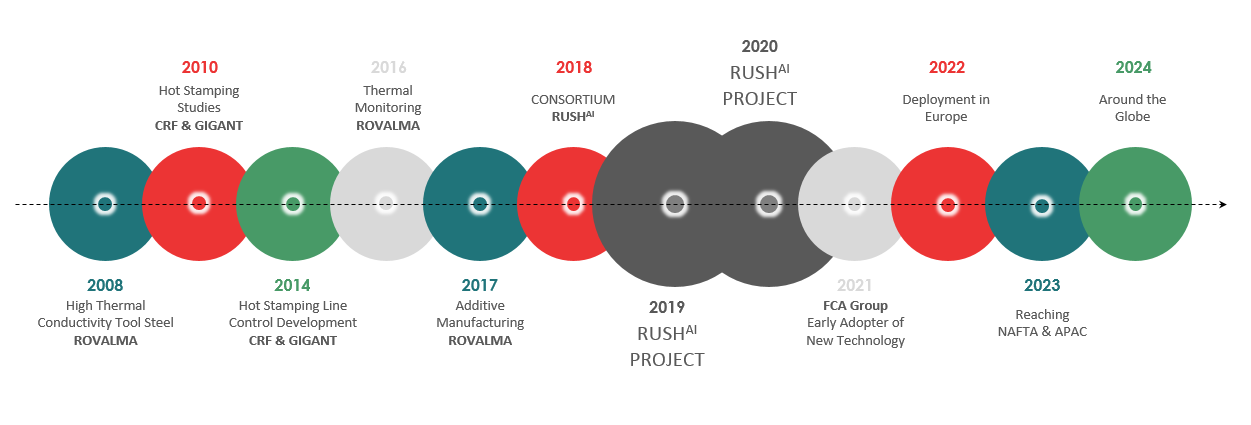

WHO WE ARE

The RUSHAI Consortium is based on exploiting the synergy of the technological skills and industrial aspirations of the 4 project partners to successfully overcome the technological challenges posed by this ambitious project to the socioeconomic benefit of European citizens and the environment at large.

LATEST NEWS