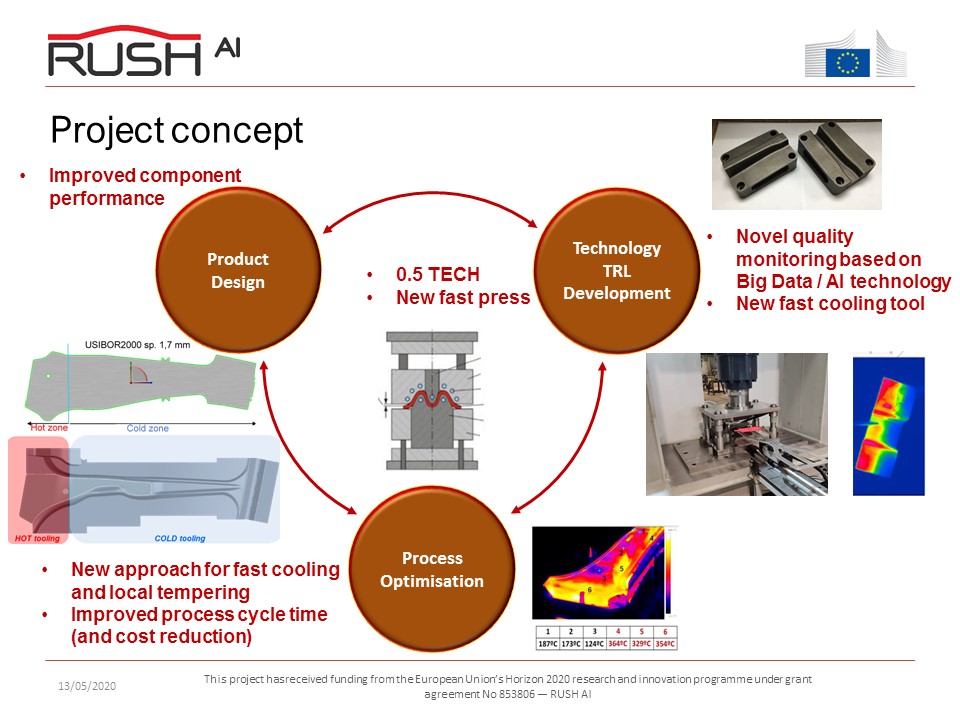

The RUSHAI technology provides great flexibility for the hot stamping (press hardening) of a large range of blank thicknesses, with the possibility to locally control the cooling rate and, hence, pave the way towards making complex tailored components.

RUSHAI unlocks new opportunities to manufacture very thin, hence very light, components with extraordinary strength and crashworthiness. It enables an estimated 30% reduction of component weight, paving the way towards electromobility, while at the same time reducing component production costs by a projected 70%. This will generate a strongly increasing market demand for Ultra High Strength Steel (UHSS) hot-stamped Body in White (BIW). Exploiting this technology, mechanical presses may replace in the future hydraulic presses, providing even faster cycling time.

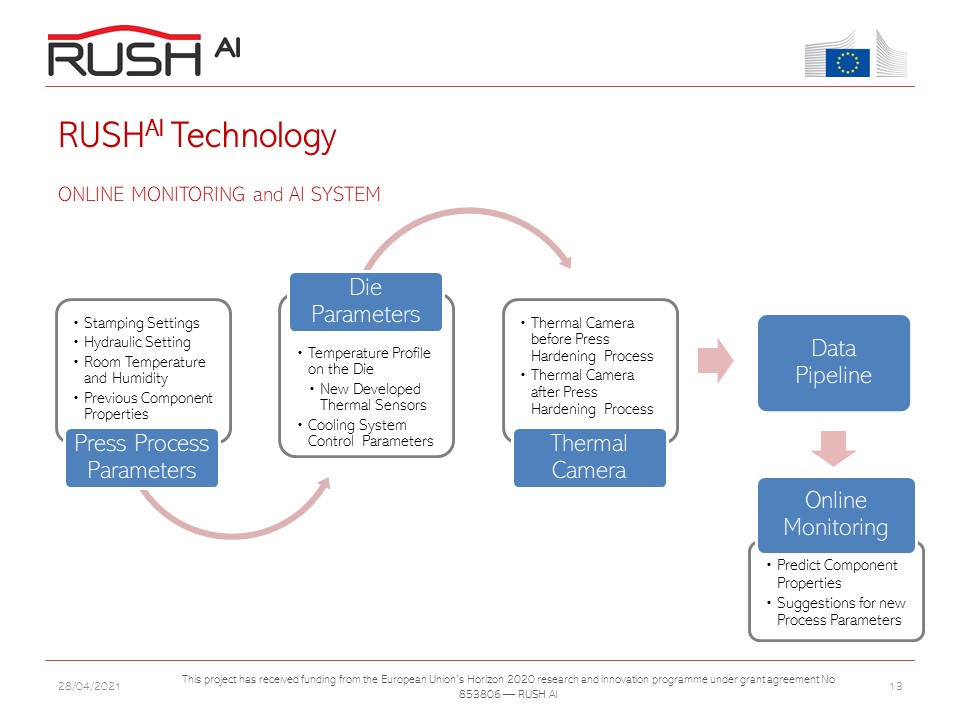

RUSHAI technology enables hot stamping to go one step beyond Industry 4.0 towards Advanced Manufacturing. The RUSHAI approach creates a basis for a break-through quality assurance system by autonomously controlling the quality of every single component produced with minimum human intervention. RUSHAI‘s intelligent quality control system increases the possibilities of producing more accurate and tailored complex components and facilitates the main objective of enabling a smart, fast and functional hot-stamping process that reduces time, component scraps, weight and cost, while improving passenger safety.

RESULTS

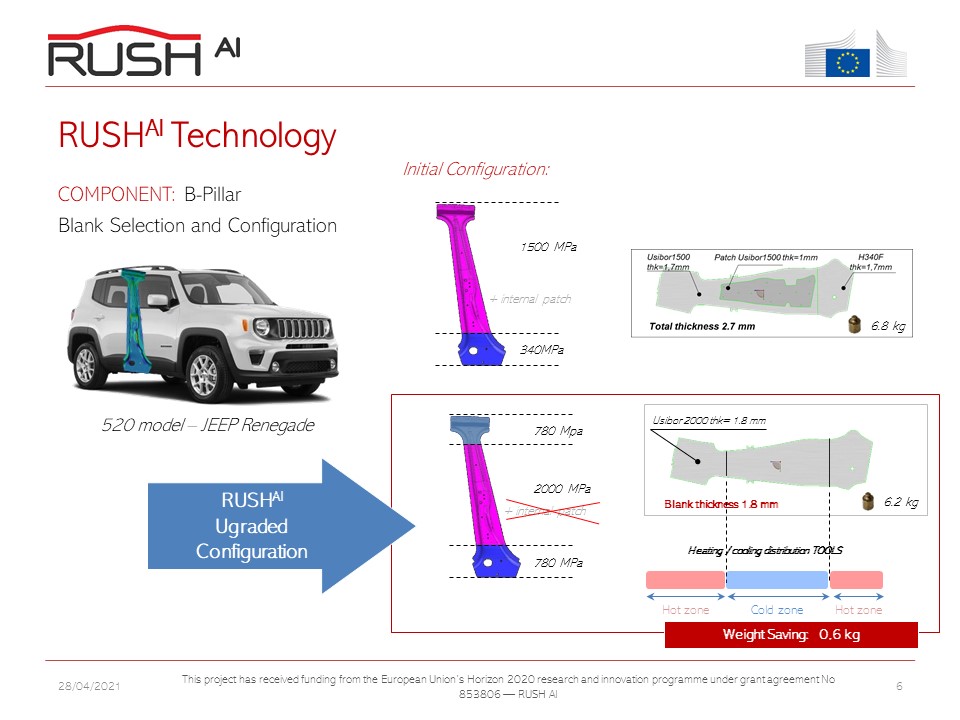

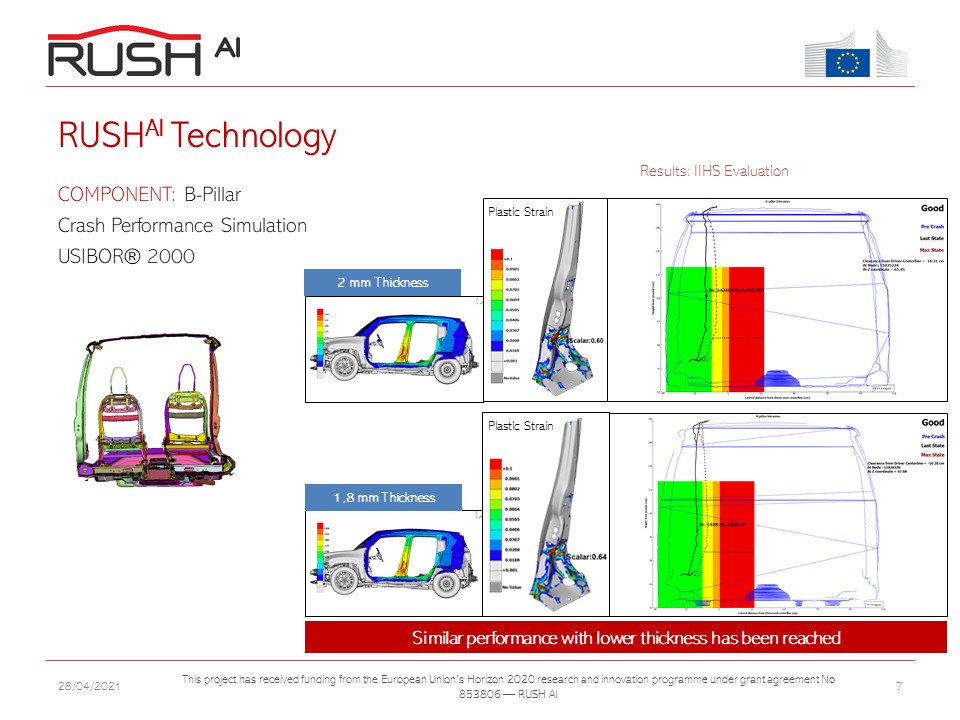

From the project start, April 2019, a new automotive B-pillar in 22MnB5 has been redesigned according to the component performance targets with the direct support of FCA Product Engineering department. The new component is a monolithic material approach without reinforced patches and with a tailored tempering process to enable a performance local optimisation. The overall thickness has been settled to 1.8 mm together with the new USIBOR®-2000 material has been adopted.

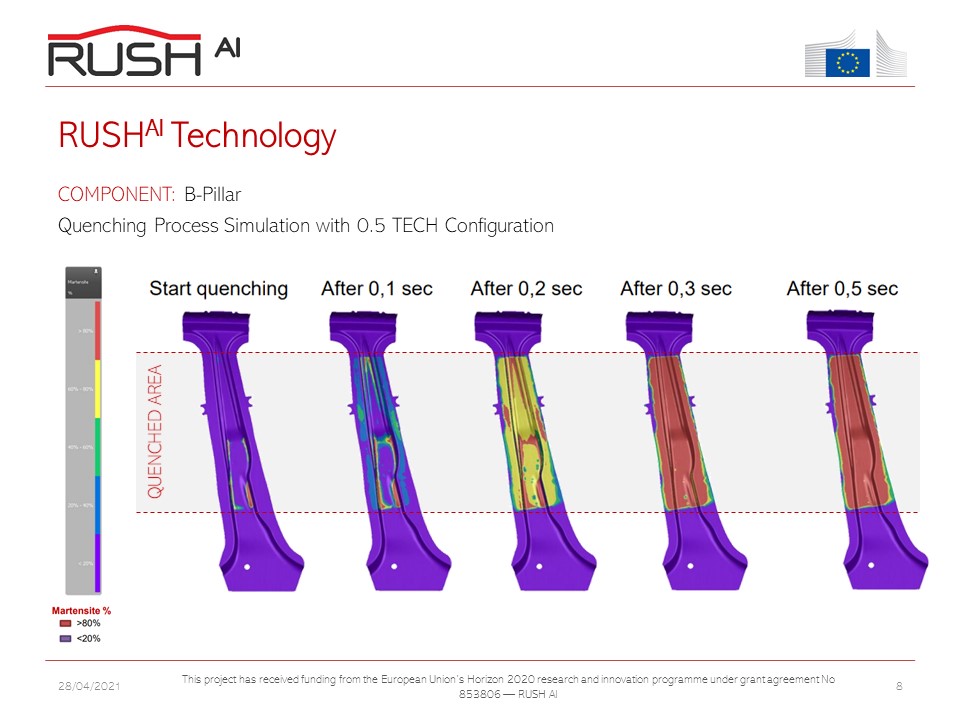

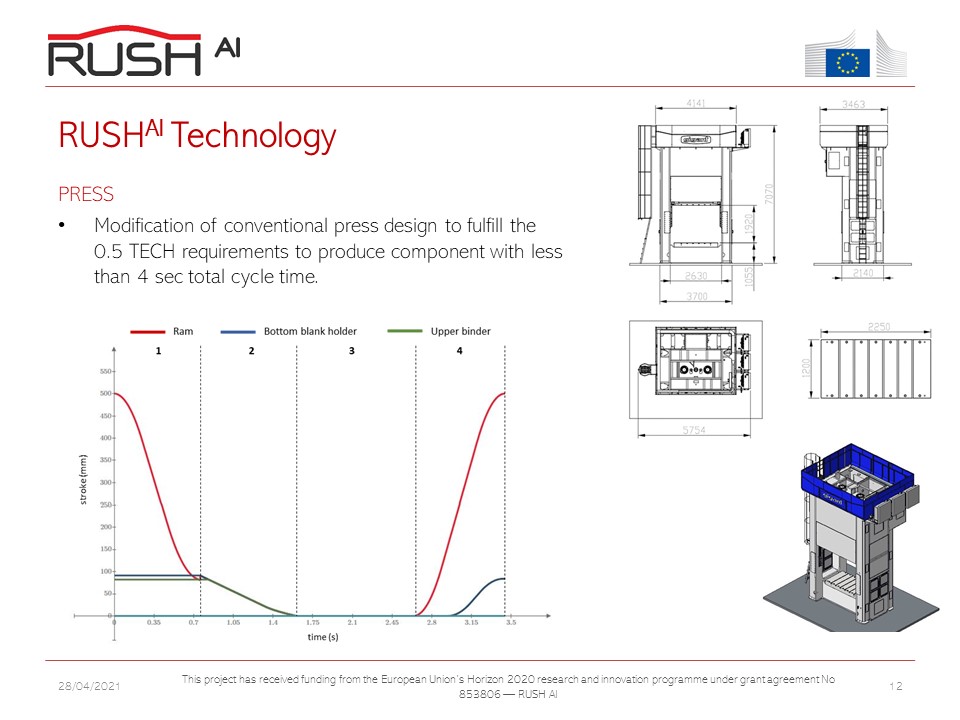

The fast stamping process was defined together with its requirements: the current SOTA quenching process estimated on 6 seconds was challenged through the RUSHAI technology to a >90% time reduction on the selected component (< 1 second). All these activities were performed in WP1 and WP3.

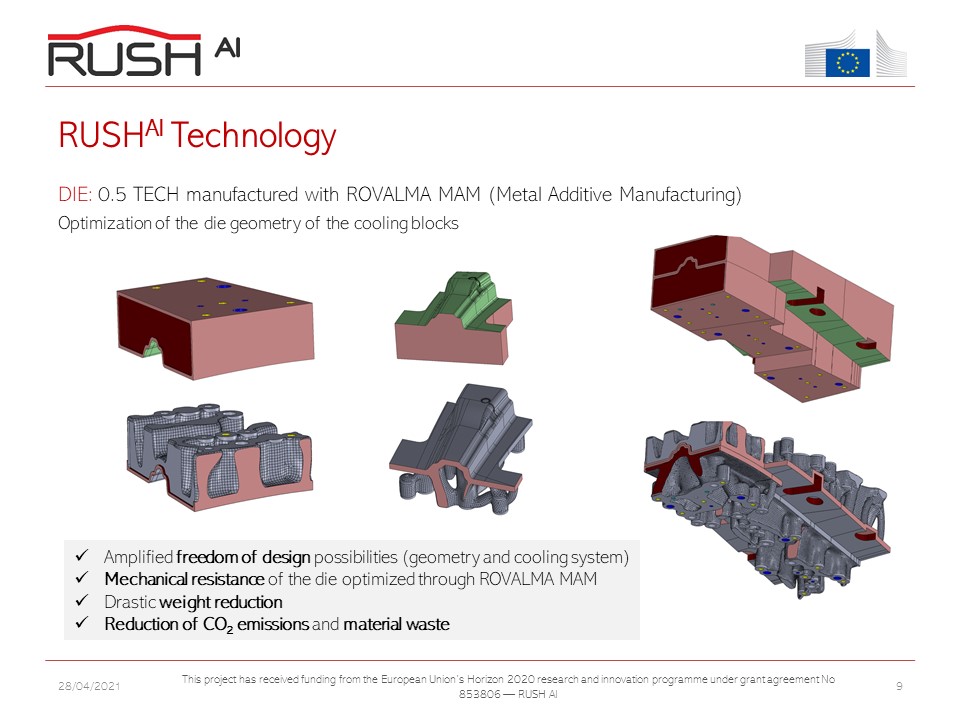

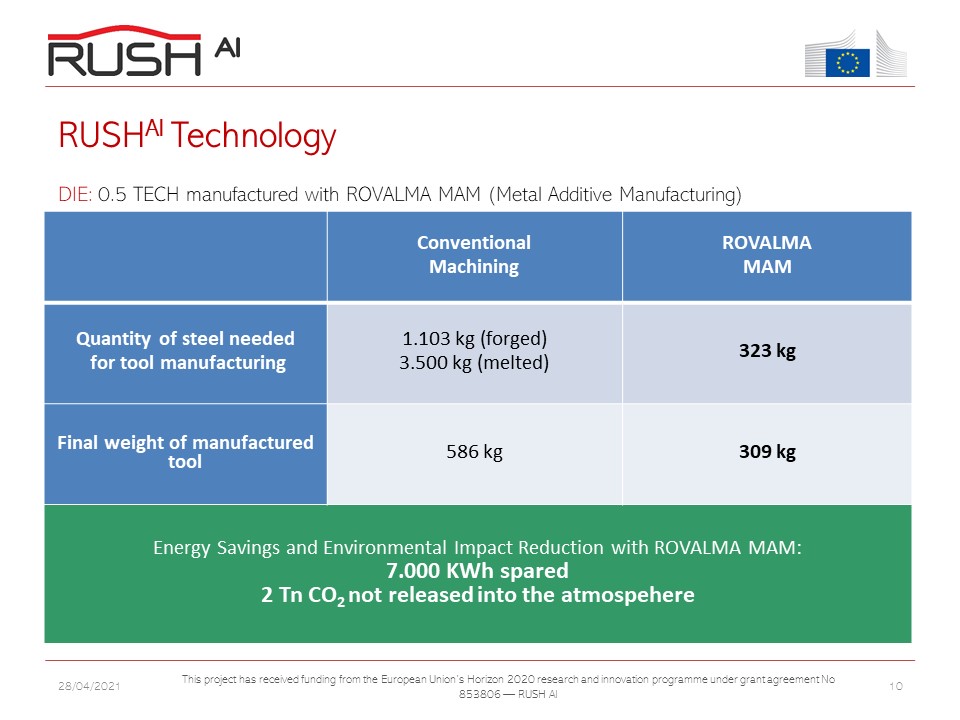

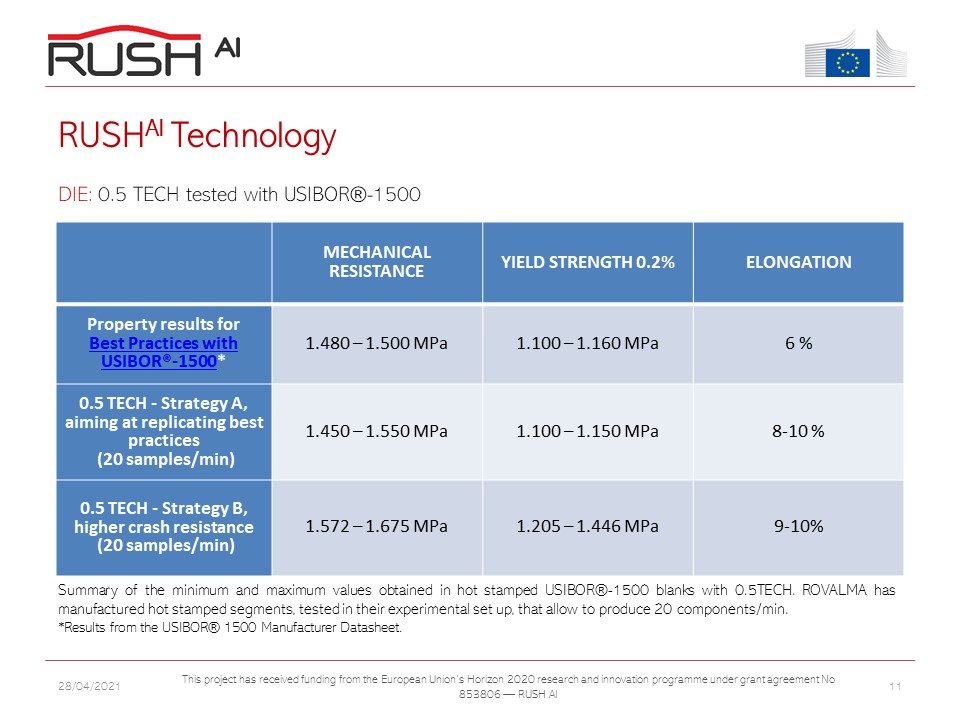

WP2 was dedicated to the innovative 0.5 TECH tool die development, including its material optimisation. The new tool has been redesigned to fulfil the fast cooling process specification and the final component performance local distribution.

In WP3, after the B-pillar component redesign, the activity was focused on the relevant press line specification definition (press cycle). FE simulation provided the force and velocity required in press cycle. A preliminary investigation on feeder units’ technology has been conducted to select the most suitable solution that guarantee short loading and unloading time. According to the press line specification, the press system design was started (currently running). So far the already completed activities are: press cycle parameters and press structure definition, feeder cycle determination, oven architecture, thermal cycle and press and line parameters to be monitored for process control. WP4 is focused on the process monitoring and quality control. Within this WP, the data acquisition infrastructure with the envisioned architecture has been defined, defining all the necessary sensors for the Quality Monitoring System (QMS) to be combined via the data pipeline. The data acquisition and process control development is currently in progress and a Big Data / AI software of DATASTORIES has been adapted to support the following two new features at a Proof-of-Concept level: 1) the multi-objective optimization and the 2) capability of reverse-engineering the obtained models by means of the internal optimizer.

In the second project year the 0.5 TECH tool die will be completed for final component production (WP2). After an initial experimental set-up campaign to demonstrate the fast cooling capability on component production the new fast press line will be installed and equipped with the 0.5 TECH tool die for a final RUSHAI objective exploitation. WP5 is focused on the final demonstrator activity. In the next months, the new tool die will be completed, assembled with all the inserts, and tested at one demo site by a dedicated experimental campaign. With these results, the data acquisition and process control systems will be tested and validated. Both the activities will be essential for the final RUSHAI demo activity on the new fast press that will be manufactured and installed in the final demo site. There the full system (0.5 TECH tool die, feeding system and fast press) will be validated in industrial condition. A drastic reduction of press closed and open die times, reaching a total cycle time of 5.0 seconds at pilot installation will be reduced below 4.0 seconds one year after FTI project concludes with incorporation of intelligent real-time and on-line quality control monitoring system to reduce scraps, detect the tailored component area and control the process with corrective countermeasures.

Further results will be published here.